This product is not available for new orders.

| Services Available |

|---|

Overview

The 237 measures leaf wetness by determining the electrical resistance on the surface of the sensor (a wet surface is less resistant). It is primarily used to determine the percentage of time that a leaf surface is wet, versus the time it is dry.

Note 1: The 237 is designed for short duration ac excitation; dc excitation or continuous ac excitation may damage the sensing grid.

Note 2: Users of the 237F should contact Campbell Scientific for a copy of the manual.

Read MoreBenefits and Features

- Sensor is shipped unpainted so customer can choose appropriate surface finish that best fits their application

- Imitates characteristics of a leaf

Technical Description

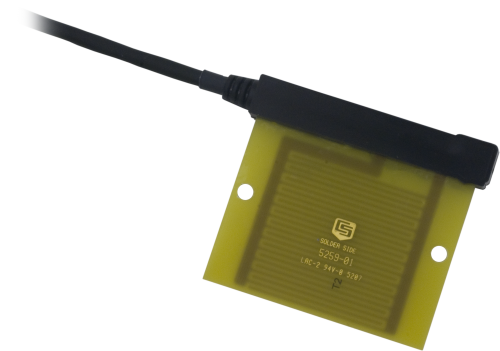

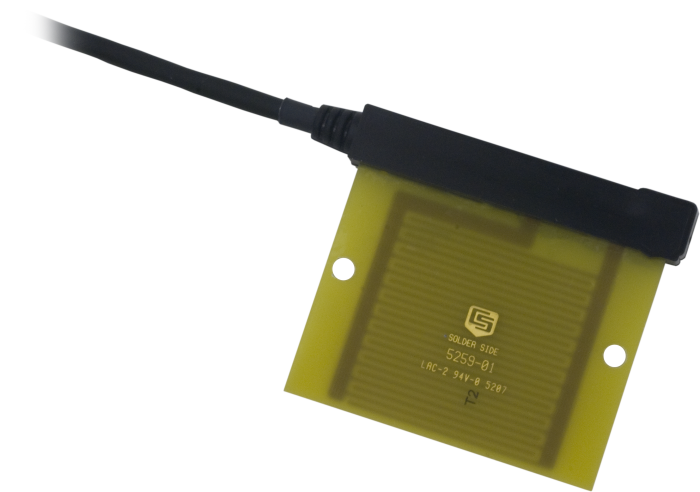

The 237 consists of a circuit board with interlacing gold-plated fingers. Condensation on the sensor lowers the resistance between the fingers, which is measured by the datalogger.

Droplets must touch two fingers simultaneously to change the sensor resistance. For this reason, the 237 is typically coated with flat latex paint, which spreads water droplets. The colour and type of paint affect sensor performance. Campbell Scientific supplies the sensor unpainted allowing customers to determine the appropriate paint to apply to the sensor's surface. The appropriate pigmentation should closely emulate the properties of a typical leaf.

Calibration

The resistance of the sensor at the wet/dry transition point should be determined. A sharp change in resistance occurs in the wet-dry transition on the uncoated sensor; normally the transition is between 50 and 200 kohms. Coated sensors have a poorly defined transition which normally occurs from 20 kohms to above 1,000 kohms. For best results, the leaf wetness sensor should be field calibrated since the transition point will vary for different areas and vegetation.

Images

Related Products

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

Data Logger Considerations

The 237 requires one single-ended analog input and one switched excitation channel for measurement.

Specifications

| Resistance at Wet/Dry Transition |

|

| Operating Temperature Range | 0° to 100°C |

| Short-Term Survivability Temperature Range |

-40° to +150°C Sensor may crack when temperature drops below -40°C. |

| Painting | Sensor is shipped unpainted so customer can choose appropriate surface finish to best match the application. |

| Hole Spacing | 6.73 cm (2.65 in.) |

| Hole Diameter | 0.54 cm (0.213 in.) |

| Dimensions | 7.6 x 7.1 x 0.64 cm (3.0 x 2.75 x 0.25 in.) |

| Weight | 91 g (3 oz) with 3.05 m (10 ft) cable |

Resources and Links

Product Brochures

Manuals

FAQs for

Number of FAQs related to 237: 13

Expand AllCollapse All

-

Approximately 0.9 mm.

-

Variable, but always negligible. The theoretical maximum for each measurement is 5000 mV at 5 µA for less than 3 ms.

-

Yes. The thermal characteristics of the 237-L are probably different from those of any surrounding objects, including leaves. Consequently, the 237-L will dry at a rate different from surrounding objects, including leaves.

-

Paint only with a flat latex paint. Usually, a high-quality, white, flat latex paint is used with a tiny amount of pigment.

-

The mounting method used depends on the application. In plant canopies, consider mounting the 237-L so that it receives the least amount of solar radiation at noon. This means tipping the sensor, electrodes up, so that its sensing surface is parallel to the plane of the ecliptic. Tipping the sensor also minimizes the chance of water puddling on its surface.

On non-living surfaces, such as a man-made structure, consider mounting the 237-L flat against a flat surface on the shady side. This will cause the 237-L’s thermal characteristics to be more similar to those of the surface being studied.

-

Only in the most basic sense. The signal output from the 237-L can only be interpreted as an indication of the presence of a conductive material bridging the two electrodes on its surface. If the circuit is open (infinite resistance or zero conductance), there is no conductive material. If the circuit is closed, there is conductive material.

The primary use of the 237-L is to indicate the presence of free water on the surface of surrounding objects. The thermal characteristics of the 237-L are probably different from those of any surrounding objects, including leaves. Consequently, the 237-L will dry at a rate different from surrounding objects, including leaves. Data from the 237-L are only interchangeable from measurement site to measurement site if the following are true:

- Each 237-L is prepared and maintained in the same way.

- Each 237-L is mounted in nearly identical environments.

Plant disease researchers found that if a 237-L sensor was placed in a plant canopy at a consistent position, with a consistent coating of a spreading material on its surface (that is, paint), they could estimate when free water was in the plant canopy. From this discovery, they were able to formulate disease emergence models. The resulting models tolerate significant deviation in moisture-presence data. Even so, use of a different spreading material, or difference in sensor positioning, may invalidate the data.

-

No. The sensor signal can only be interpreted as either wet or dry.

-

The 237-L is not designed to be used as a conductivity sensor. To our knowledge, a few people have tried this but have been unsuccessful.

-

Both leaf wetness sensors are compatible with all Campbell Scientific data loggers. However, the 237-L is often used in large legacy networks that rely on the 237-L for data continuity. The 237-L does require painting and field calibration, whereas the LWS does not.

Case Studies

The Delaware Environmental Observing System (DEOS) is a real-time system dedicated to monitoring environmental conditions......read more

The West Texas Mesonet (WTM) project was initiated by Texas Tech University in 1999 to......read more

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences