Ideal for monitoring solar panel temperatures

Overview

The CS220 is a thermocouple that measures the temperature of a surface by direct contact. It typically monitors the temperature of a solar panel, but it can also monitor the temperature of other devices. This thermocouple easily interfaces with our dataloggers, and it is ideal for solar energy applications.

Read MoreBenefits and Features

- Well-suited for solar energy applications

- Thermocouple tolerance meets ASTM E230-ANSI MC 96.1 (reference junction at 0°C)

- Easy to install

- Compatible with most Campbell Scientific data loggers

Technical Description

The CS220 uses a 24-AWG, twisted pair, shielded, fast response type E thermocouple. Type E thermocouples consist of a chromel wire and a constantan wire joined at a measurement junction. A voltage potential is generated when the measurement end of the thermocouple is at a different temperature than the reference end of the thermocouple. The magnitude of the voltage potential is related to the temperature difference. Therefore, temperature can be determined by measuring the differences in potential created at the junction of the two wires.

A reference temperature measurement is required for thermocouple measurements. The temperature sensor built into many of our dataloggers' wiring panel typically provides this measurement.

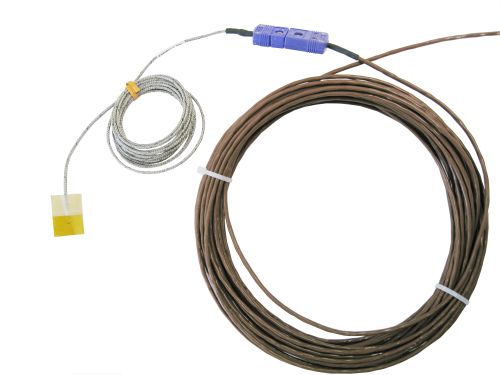

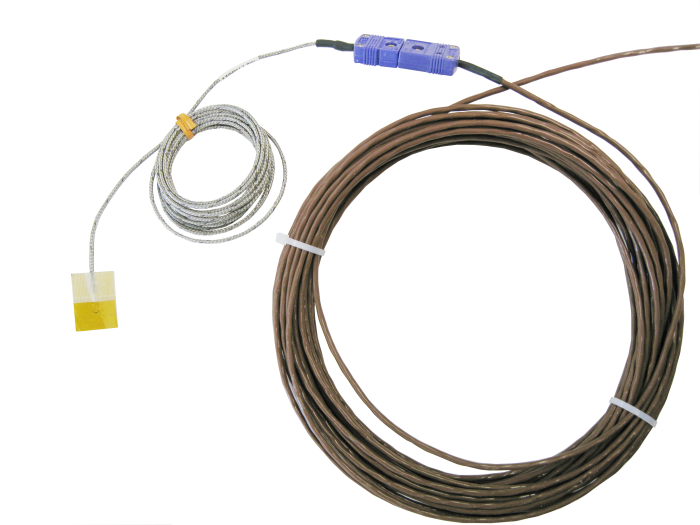

The CS220 consists of a stainless-steel overbraided cable and a thermocouple extension cable. Adhesive on one end of the overbraided cable secures the sensor to the solar panel. The mini connectors of the thermocouple extension and overbraided cables attach to each other. The pigtails of the extension cable connect to the datalogger.

The CS220 can provide the temperature on the back of a solar panel, which is an important measurement in solar energy applications. The output of a solar panel is affected by its temperature. As the temperature of the solar panel increases, its output decreases.

Images

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR200X (retired) | ||

| CR216X (retired) | ||

| CR3000 | ||

| CR5000 (retired) | ||

| CR800 (retired) | ||

| CR850 (retired) | ||

| CR9000X (retired) |

Additional Compatibility Information

Installation

The CS220 usually adheres in the center of the back panel of a solar module. Once the mounting location is determined, clean the back panel surface. Use extreme caution removing the masking paper from the measurement end of the thermocouple; damage can occur if masking paper is not removed carefully. Once masking paper is removed, firmly press thermocouple to the panel. Adhere the cable strain relief 2 to 3 in. from the end. Connect the mini connector on the stainless-steel overbraided cable to the mini connector on the thermocouple extension cable. Wire the pigtails of the thermocouple extension cable to the data logger, as determined by the data logger program/wiring table.

Multiplexers

If large numbers of CS220s need to be measured, the AM25T Thermocouple Multiplexer is recommended.

Data Logger Considerations

One differential channel per probe is required; a thermocouple reference junction at the data logger is also required.

Programming

The CS220 is measured by the TCDiff instruction in CRBasic and by Instruction 14 (Differential Thermocouple) in Edlog. The CR200(X)-series, CR500, and CR510 dataloggers do not have thermocouple measurement instructions and are therefore not compatible with the CS220.

Reference Temperature Measurement

A reference temperature measurement is required. Options for measuring the reference temperature include:

- Thermistor built into the CR800, CR850, CR1000, CR3000, or CR5000 wiring panel

- PRT built into the wiring panel of the CR9050 or

- CR9051E input module for the CR9000X Measurement and Control Datalogger

- PRT built into the wiring panel of the CR723T input card for the CR7 Measurement and Control Datalogger

- CR10XTCR thermistor that connects to the CR10X wiring panel

Specifications

| Sensor | Type E thermocouple |

| Measurement Description | Back-of-module temperature |

| Operating Temperature Range | Up to 260°C |

| Thermocouple Type | Chromel-Constantan |

| Typical Output | 60 μV/°C |

| Thermocouple Tolerances |

Meets ASTM E230-ANSI MC 96.1 Special Limits of 1.0°C or 0.4% (0° to 900°C). Reference junction at 0°C. |

| Maximum Temperature of Adhesive | Adheres up to 260°C. |

| Accuracy | Refer to the Thermocouple Measurement section in the data logger manual. |

| Response Time | 0.15 s |

| Sensitivity | +1°C |

| Length of Stainless-Steel Braided Cable | 1.0 m (3.3 ft) |

| Thermocouple Length | 2.54 cm (1.00 in.) |

| Thermocouple Width | 1.91 cm (0.75 in.) |

| Weight | 238 g (8.4 oz) with 15.24-m (50-ft) cable |

Resources and Links

Product Brochures

FAQs for

Number of FAQs related to CS220: 2

-

Magnetic fields do affect thermocouples, but Campbell Scientific data loggers are designed for thermocouple measurements and have built-in tools to make the best measurements possible.

Some suggestions for better measurements:

- Use a thermocouple with a shield that is tied to ground on the data logger side.

- Use the TCDiff() and TCSe() instructions. In those instructions there is a 50 and 60 Hz noise filter that can be used.

- Never run thermocouple wires in the same conduit as ac voltage.

-

Campbell Scientific recommends approximately 100 ohm loop resistance. This means that with a Type E thermocouple, based on 24 AWG wire, the maximum is approximately 100 feet. It is possible to exceed that distance, but it is not recommended. OMEGA provides a “Resistance vs. Wire Diameter” table that displays the resistance per double foot. See page H-8 of this PDF. Using this table, it is easy to determine how many feet can be run with any particular gauge.

Privacy Policy Update

We've updated our privacy policy. Learn More

Cookie Consent

Update your cookie preferences. Update Cookie Preferences